汽车网络的传输要求和数据载荷持续大幅增加,这一趋势还将延续下去。为应对未来的需求,我们需要高速、高带宽的汽车以太网,这同时也意味着,我们必须采取适当的ESD保护措施,确保我们驾驶时安全无虞。通过高效的系统级ESD设计(SEED),一种全新的系统级ESD仿真方法,它能帮助开发出符合行业要求的新保护器件。

正如上一篇博客“开放技术联盟:采用正确的ESD保护方案”中提到的,为了满足对高数据速率、数据安全性和灵活性的日益增加的需求,我们需要放弃异构车载网络(LIN、CAN-FD和FlexRay),转而使用同构以太网架构。

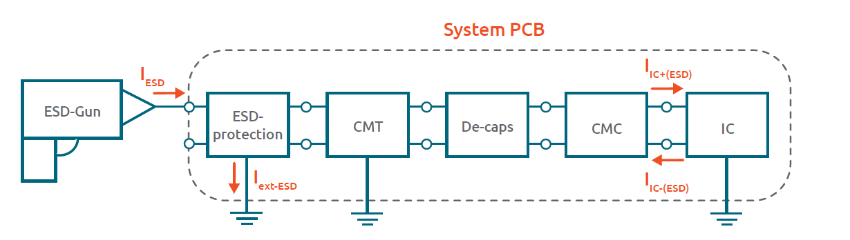

开放技术联盟(单对以太网)特别兴趣小组(SIG)的一个关键目标是实现现有的IEEE 100BASE-T1和1000BASE-T1物理层规范的部署,并制定一些补充协议规范以实现彼此间的互通互融。为了实现这一目标同时应对汽车中的独特操作条件,需要将ESD保护器件置于连接器旁边,而不是置于共模扼流圈(CMC)和PHY之间,这样不仅能够保护PHY,还将保护CMC和无源器件。

在《面向ESD抑制器件的IEEE 1000BASE-T1 EMC测试规范》文档中,开放技术联盟提出一种名为“ESD放电电流测量”的测量方法。通过该方法可以估算出整体系统级ESD稳健性。此项测试可以确定进入PHY的残余电流,从而确定对应于人体模型要求的ESD稳健性等级。

SEED提供系统级ESD方法

ESD设计面临的一个基本问题是预测系统级稳健性。人们常常误以为系统级稳健性取决于各个组件的稳健性。相反,这取决于多方面因素:

- 系统中最薄弱器件(通常是要保护的SoC)的稳健性

- 保护器件的属性

- 信号路径中的其他元件的属性

- 由电路板和安装导线引起的寄生效应

SEED的概念(如ESD应用手册——现代接口的保护概念、测试和仿真第5章所述)是将所有这些参数视为等效电路或类似电路的仿真,从而预测系统级稳健性。系统的等效电路表示(包括SoC)与保护器件模型相连接,以评估保护性能。除了基于SPICE的仿真,Verilog-A和基于网络参数模块的自定义模型等其他仿真工具可以相结合以实现系统仿真。

开放技术联盟以太网ESD保护

在开发行业首个面向100/1000BAASE-T1汽车以太网系统的符合开放技术联盟标准的硅基ESD保护时,Nexperia使用高效的系统级ESD设计(SEED)方法来模拟ESD放电电流测量。

通过使用SEED方法,Nexperia可以研究外部ESD保护器件的寄生电感、触发器、回弹行为等不同参数对系统级ESD稳健性的影响。通过此研究,开发人员还可以预测其他无源器件在ESD事件期间遭受的电磁应力等级。如需了解有关如何应用该方法的完整描述与说明,请查阅我们的白皮书:运用SEED设计方法,根据开放技术联盟100BASE-T1规范高效预测ESD放电电流。

最终,我们获得了面向100/1000BASE-T1以太网的首个真正符合开放技术联盟标准的ESD保护。与变阻器等传统技术相比,硅器件提供明显更高级别的保护,系统级稳健性高达30kV,其性能也会随时间下降。PESD2ETH100-T和PESD2ETH1G-T是现代汽车以太网接口的首选,采用低成本小型SOT23表面贴装塑料封装。