对于系统设计而言,人们总是尽可能地采用最理想的解决方案来达到最高效的设计。与平面整流器相比,沟槽肖特基整流器让我们与理想的解决方案更近一步。

为了追求更高效的设计,我们会持续地优化我们的电子系统。对于许多系统级电路,尤其是电源转换电路,平面肖特基势垒二极管一直是传统的主流设计方案, 但平面肖特基二极管需要在正向压降和漏电流等关键性能指标方面做出权衡。同样,在电磁敏感的应用中,传统的肖特基势垒二极管也不是理想的无损和瞬时整流解决方案。

理想的整流器

理想的整流器应具有低正向压降、高反向阻断电压、零漏电流和低寄生电容。但在实际应用中要实现这一点,就必须在这些参数间做出取舍。

例如,采用某些金属可以使金属-半导体界面上的正向压降做到最小化,但必须以较高的反向泄漏电流为代价。或者,如果使漂移区变宽以获得更高的反向阻断电压,那么跨在肖特基结的低正向压降的优势可能会减弱、甚至消失,这也是为什么肖特基整流器的反向阻断电压通常限制在200V以下。

在硅上刻蚀沟槽

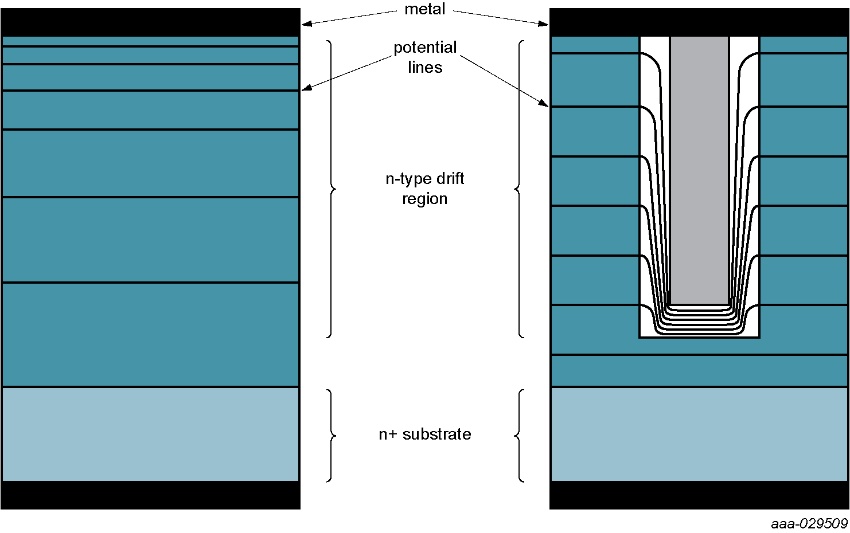

因此,在不增加反向泄漏电流的情况下提升反向阻断电压是目前平面肖特基整流器设计所面临的一个挑战。平面肖特基的局限性在于等电位的势垒线倾向于聚集在金属电极附近而不是衬底,当在表面附近超过临界电场时,会导致较早地击穿。而通过将trench沟槽蚀刻到硅中并填充导电的多晶硅,可有效地耗尽反向漂移区内的漂移电子,并使漂移区电场均匀分布。

这意味着Trench 沟槽肖特基整流器系列在VF和IR之间实现了很好的平衡。与平面肖特基二极管相比,沟槽肖特基器件具有更宽的安全工作范围(SOA)。由于对热失控的鲁棒性,这使得它们在环境温度较高的应用中成为理想选择。

与平面肖特基二极管相比,沟槽肖特基整流电路中的额外RC提供了另一个好处,它提供了更好的电磁兼容性,因此沟槽整流器更适合于电磁敏感的应用领域。

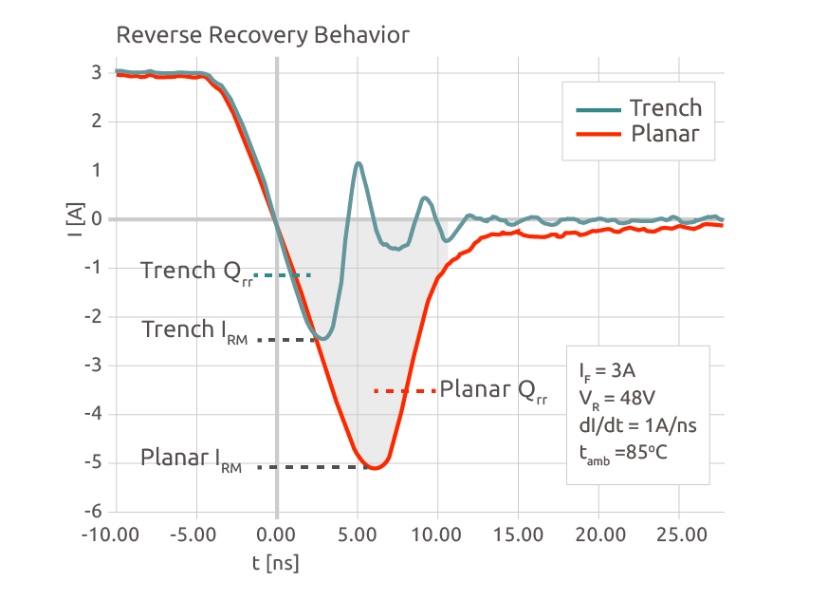

The Trench Schottky diode has much less Qrr compared to the planar Schottky. This results in lower switching losses when used in a switch-mode converter circuitry. EMI measurements revealed that the observed “ringing” of the Trench Schottky does not affect the electromagnetic emission levels.

总之,沟槽肖特基整流器是首选

通过将肖特基与Trench技术相结合,最新的Trench肖特基整流器带来了许多性能优势。沟槽肖特基二极管在正向压降和漏电流之间提供了更好的平衡。它们还具有出色的EMC性能以及对热失控效应的鲁棒性。

只有在考虑寄生电容时,设计者才需要注意——通常,单位面积下,沟槽肖特基整流器的总寄生电容高于平面整流器。因此,如果在具有较高的开关损耗的系统应用中,需要更低电容的整流管,平面肖特基是更好的选择。然而,在大多数损耗是由于正向压降或漏电流引起的应用中,沟槽整流器无疑是更棒的选择。