In an ideal world, mains power supply failures would never happen. However, the real world is anything but ideal, which means backup power sources are required to ensure that equipment does not stop functioning if the primary power source fails (due to a lightning strike, for example) or is damaged if a backup battery is inadvertently inserted with the wrong polarity. Traditionally, Schottky diodes have been key components in these OR-ing circuits, but they have inherent limitations which mean designers are increasingly opting for the more recently developed ‘ideal diode’ instead.

This blog explains the difference between ideal diodes and other diode types and the advantages ideal diodes offer for protecting OR-ing circuits in various use cases. It also discusses the features of Nexperia's newly introduced ideal diodes and the advantages they deliver over other similar competing devices.

The diode journey from P-N, to Schottky, to ‘Ideal’

Standard P-N semiconductor diodes, which are constructed using a positive (P+) and negatively doped (N-) semiconductor material, are simple electronics components that allow current to flow in only one direction. A feature that makes them perfect for blocking the flow of undesirable reverse currents in electronic circuits. However, the physical properties of these devices mean they require a potential difference (voltage) of approximately 0.6 V between the positive (cathode) and negative (anode) terminals before current can flow. Since the power dissipated by these devices is the product of this forward bias voltage (VF) and the conducted current (I), power is wasted because this bias voltage cannot be transferred to the load being driven.

One obvious way to reduce the amount of wasted power is to reduce VF, and Schottky diodes were developed to help achieve this. Schottky diodes differ from standard diodes in that they use a combination of metal and negatively doped semiconductor material to lower VF to 0.3 V (typical), but this value can vary from 0.25 to 0.5 V. While this is an improvement on standard semiconductor diodes (reducing power consumption by 50%), some power is still wasted.

In an ideal world, diodes would not require any forward voltage for current to flow (VF = 0,). However, since their material properties prohibit this, designers set about developing a component that would mimic the behavior of a diode, but which would require the minimum possible VF to operate. This resulted in the development of integrated circuit (IC) components that only require VF in the order of tens of millivolts (mV) and which were therefore labelled (admittedly with the benefit of some poetic license) as ‘ideal’ diodes.

It is important to note that the term ‘ideal’ is not intended to suggest that VF = 0 for these devices, merely that their behavior is as close to ‘ideal’ as currently possible. And ironically, ideal diodes are not constructed using diodes but instead use a pass MOSFET whose forward voltage and on-resistance (RDSon) are regulated by varying the gate voltage in response to changes in load current, to deliver the desired behavior.

When VIN > VOUT in low-load current applications, the feedback amplifier drives the PMOS gate, regulating its drain-source voltage to have a constant value, VREG. At higher current levels, the transistor is fully enhanced to minimize its on-resistance RDSon(MIN).

Alternatively, when VIN < VOUT, the amplifier drives the PMOS gate high, thereby turning off PMOS and blocking the flow of reverse current.

While the major advantage of ideal diodes over Schottky’s is clear, i.e. >10x lower forward-biased power dissipation, another is their lower reverse leakage current (typically > 4x) when VOUT > VIN. This is important in applications using a battery as a backup power supply (power OR-ing), where reverse DC leakage current can cause unwanted battery charging that could negatively impact its useable lifespan.

Nexperia’s NID5100 and NID5100-Q100 are even more ‘ideal’

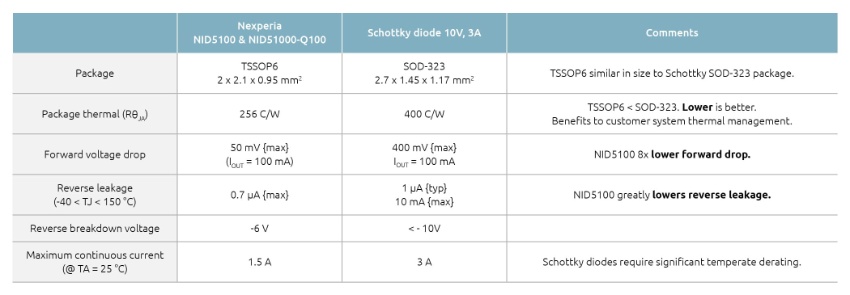

Nexperia recently added two new ideal diode ICs to its continuously growing portfolio of power devices. The NID5100 is suitable for standard industrial and consumer equipment while the NID5100-Q100 has been qualified for use in automotive applications. The gate voltage of an internal PMOS transistor in these ICs regulates the ‘anode’ to ‘cathode’ voltage of the diode to be 8-10x lower than the forward voltage drop of similarly rated Schottky diodes, while also helping to reduce reverse DC leakage current by up to 100x. Nexperia’s new ideal diodes offer several advantages over other competing ideal diodes - for example, in forward conduction mode, the NID5100 and NID5100-Q100 regulate VF to be only 31 mV (10 mV lower).

The NID5100 and NID5100-Q100 are designed for 1.2 to 5.5 V systems and rated for 1.5 A continuous current while consuming only 240 nA (typical) quiescent current. They also support pulsed loads up to 2.5 A and can tolerate reverse polarities down to -6 V, thereby helping to prevent downstream loads from experiencing potentially destructive voltage reversals caused by wiring errors or incorrectly inserted batteries. A unique aspect of these devices is that also be used to simultaneously provide reverse polarity protection (RPP) and reverse current blocking (RCB) – these features are mutually exclusive in ideal diodes offered by other suppliers.

The status pin (ST) on the NID5100 and NID5100-Q100 is an open-drain output used to indicate if the device is operating in regulated forward conduction mode or is in a reverse biased (or disabled) state. This facilitates priority OR-ing of two power supplies with similar voltage levels using only one general purpose IO pin (GPIO) on a microcontroller. These ideal diodes are available in small TSSP6/SOT363-2 leaded plastic packages measuring only 2.1 mm x 1.25 mm x 0.95 mm, which exhibit superior thermal characteristics to similarly sized Schottky diodes.

While the truly ‘ideal’ diode (VF=0) is aspirational, Nexperia’s NID5100 and NID5100-Q100, with VF = 31 mV are closer to the ‘ideal’ than others currently available. These ICs, which also support several unique features, simplify load sharing of multiple power supplies and batteries in various applications like e-meters, IoT and building automation and home medical devices as well as automotive applications like advanced driver assistance systems (ADAS), clusters and telematic control units.