在关于动力传动系统电气化的第三篇博客中,我们首先尝试了解为什么使用48伏特系统,然后介绍48伏特起动发电机的不同安装选项。

48伏特起动发电机

2017年,整个汽车行业都实现了显著增长–从汽车OEM到小型器件制造商。汽车电气化成为备受瞩目的热门话题,特别是48伏特架构。事实上,在任何搜索引擎中搜索“48伏特”这个术语,您都会搜索到大量结果,这表明面向汽车系统的这个工程解决方案已在市场上占据了一席之地。

在前一篇博客“48伏特轻度混合动力系统的出现”中,我简要介绍了新型48伏特汽车架构及其与现有12伏特系统的差别。在这篇博客中,我们的话题将触及确定新电压水平背后的原因,并深入探讨它的主要应用之一——48伏特起动发电机。

为什么是48伏特?

显而易见的首要问题是:“为什么偏偏是48伏特?”。这是一个非常重要的问题,要记住,在上世纪90年代,人们提出了42伏特电功率标准来取代12伏特标准。虽然这个标准没有得到发展,但其意图是解决我们当今面临的一些相同问题,例如更大功率的电驱动配件及更轻的线束。选择48伏特作为标准有两个主要原因 –安全性和效率。

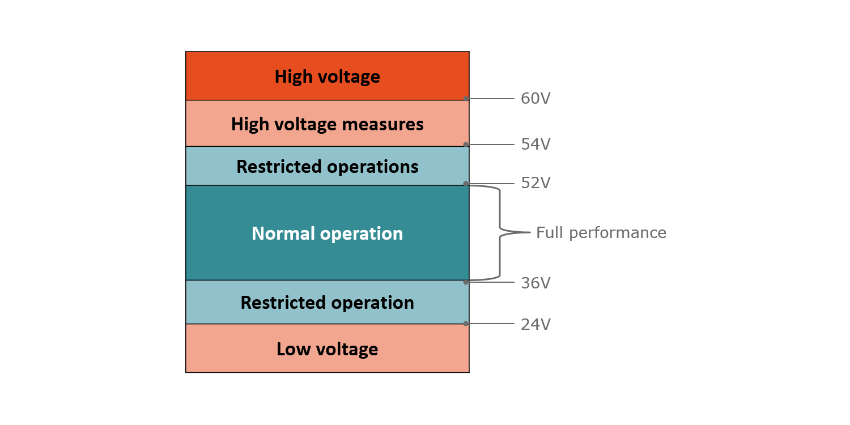

在提高电压时,涉及的一个主要问题是它可能危及人身安全。虽然有人仍在争论48伏特是否足够安全,但这个电压水平提供了我们需要的更高功率而没有进入“高电压”范围。图1显示了48伏特电池在不同电压水平下的工作情况。正如ZVEI的文档“电动出行的电压等级”所述,60伏特(直流)是安全上限最大值,高于它的电池电压都被视为过于危险。在“正常工作”范围内,电池能够达到最佳性能,但汽车内部的电子器件应该能够耐受最坏情况的高电压条件。

Figure 1: Safety voltage margins

As I’ve previously stated, the current 12-volt system is unable to cope with the growing demand for electrical power within conventional vehicles. However the 42-volt proposal was a complete replacement of the 12-volt electrical architecture while 48-volt complements it. The 48-volt battery simply adds an additional power source for new applications which also contribute to a smoother driving experience. Furthermore, the size and cost of wiring and components is significantly reduced due to the higher voltage of the 48-volt battery.

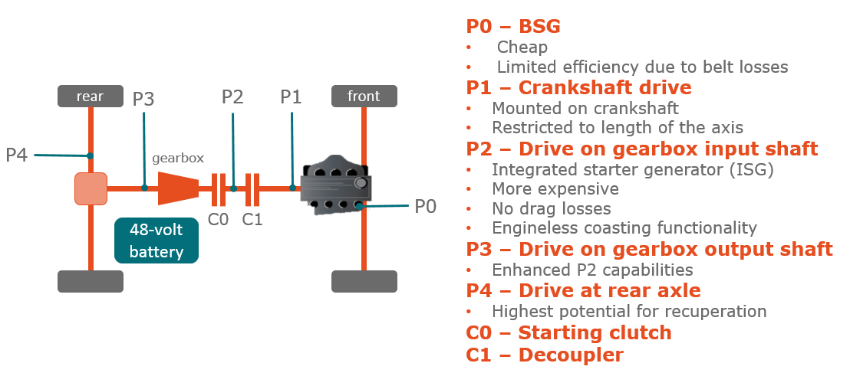

A closer look at the 48-volt starter generator options

Having a similar appearance as the car alternator (Figure 2a) but slightly bigger in size, the 48-volt starter generator’s initial topology position is at the engine’s belt. The belt-driven starter generator (BSG), also known as P0 architecture (Figure 2b) is a cost-effective solution which can provide up to a 15% reduction in CO2. Looking at some boost recuperation systems (such as Bosch’s), the maximum power ratings are around 10 kW for mechanical output in boost mode and 12 kW for electrical output during recuperation – both at 48-volts. While these numbers are rated for short periods of time, the BSG’s continuous power can reach up to 5 kW with maximum efficiency of 85%.

Figure 2a and 2b: Car alternator and P0 starter generator topology

However with tightening emission regulations, automotive Tier 1 suppliers have developed different starter generator topologies to further reduce the CO2 footprint of 48-volt mild hybrid vehicles. In ascending order, these configurations offer better emission reduction but become increasingly complex and costly.

Figure 3: 48-volt mild hybrid starter generator topologies

Crankshaft mounted starter generator (P1)

As the name suggests this solution has the starter generator mounted directly on the crankshaft (which converts the linear motion of pistons into rotary motion). This provides higher torque than the P0 architecture due to the absence of a belt drive, and with no belt losses there is greater efficiency. The maximum power required is 10 kW but the efficiency goes up to 94%. However one significant limitation of this solution is that torque requirements can be demanding, due to no torque/speed ratio between the crankshaft and the starter generator. An example of this topology is the 2010 Mercedes-Benz S400 BlueHybrid.

Shaft mounted machine (P2/P3)

Both P0 and P1 architectures are mounted on the engine, but there are other mounting options such as having the 48-volt electrical machine on the gearbox’s input/output shaft (P2/P3 respectively). By providing a mechanical disconnect, this translates to improved energy flow efficiency and allows for the provision of hybrid functions (e.g. e-drive).

The P2 architecture is ether integrated into the transmission on the input shaft or attached on the side, and results in increased energy recuperation and electrical drive capabilities. Mounting the solution on the output shaft (P3), provides the highest level of the above-mentioned benefits. The obvious disadvantage of the shaft mounted electrical machine is the cost of integration.

Rear axle mounted electrical machine (P4)

The ultimate architecture at this time involves mounting at the rear axle drive (P4). This provides the vehicle with 4-wheel drive capabilities, with the combustion engine at the front and the electrical machine at the back. Maximum power requirement of the P2-P4 architectures can reach up to 21 kW with an efficiency of 95%. Moving the starter generator closer to the rear axle also provides more hybrid functionality to the vehicle. The new 48-volt machine is able to reduce the CO2 emissions by up to 21% in urban driving environment depending on its architecture.

What is more, this high-power application requires a significant portion of electronics to drive it. Naturally power MOSFETs play a key role in these electronic modules, but they need to be capable of withstanding worst case scenarios such as excessive currents and thermal leakages. Hence, the topic of my next blog will be to delve into the semiconductor content inside 48-volt applications such as the starter generator. Stay tuned!