According to a recent report by the EU-funded project EnABLES, by 2025 around 78 million batteries powering IoT devices will be dumped globally every day if nothing is done to improve their lifespan. In the US, standard portable batteries (AA, C, D, etc.) that have been used to power a wide range of gadgets make up 20% of household hazardous material in landfills. Not to forget about the millions of unused alkaline and NiMH batteries slowly discharging in cupboards waiting to fulfil their role as annual or biannual replacements. Not only is this inefficient, but it is also unsustainable.

Small batteries play such a significant role in the modern world. Providing the power for household classics such remote controls for televisions and set-top-boxes as well as smoke / fire detectors and a plethora of wireless consumer gadgets and toys. Having a small, low-cost and efficient power source has also been key to the increase in Internet of Things (IoT) systems, covering everything from remote sensors to electronic shelf labels (ESLs). In fact, while not all are battery powered, some 9 billion connected devices existed in 2020 and this is expected to reach anywhere between 25 to 50 billion devices by 2030.*

Cost, chemistry and convenience

Despite advances in portable batteries over the years, alkaline batteries still dominate low-drain applications given their lower cost and relatively long battery life. They also tend to have much longer shelf lives than rechargeable options – so are a better fit for home emergency kits. But at the end of the day, even in low-drain applications alkaline batteries will usually only last a few years and once they have lost their charge, they become household waste. And you always need to keep some spare, because you never know when you will need to replace the battery in your wall clock or remote control.

On the other hand, rechargeable batteries are more useful when it comes to high-drain gadgets and electronics that need a lot of energy. With the ability to be manually recharged multiple times (while they can safely hold a charge), over time this makes them more cost-effective and sustainable than disposable batteries. However, they do use more complex chemistries – Nickel metal hydride batteries (Ni-MH) or Lithium-ion (Li-ion). Moreover, quite simply there is not enough lithium to power every single IoT device even taking into account moving towards 100% recycling rates (as part of the European Green Deal, the EU has collection targets of 63% in 2027 and 73% in 2030 for portable batteries).

And from a convenience perspective while replacing the occasional battery in the TV remote control or recharging the batteries in the remote-controlled toy may be annoying it isn’t too difficult. However, when you scale that up to say a few thousand Electronic Shelf Labels (ESLs) within a single retail space, then the operational costs of manually monitoring and replacing batteries becomes significant. Let alone doing that for every single ESL deployed in the world.

These are all contributing factors that support the argument to reduce dependency on primary batteries and make a better use of rechargeable batteries, moving towards more sustainable technologies.

Plug and forget

If we could extend battery life without having to manually recharge, that would dramatically reduce the number of rechargeable batteries being disposed of daily. It could eliminate the operational costs of manually checking and replacing batteries, and we would not have to worry about reaching those remote or difficult to reach systems. As an added bonus it would also make more efficient use of the rare materials involved.

Of course, this scenario is not science fiction. Energy harvesting technology has moved on significantly since the solar powered calculators of the 1980s, which were very efficient in producing just enough energy to manage a simple calculation. Fundamentally, energy harvesting systems can be designed for two goals: extend the battery lifetime or to make the product energy autonomous.

Battery lifetime extension is usually targeted at applications that consume a lot and/or are used in environments with low power budgets available. In this scenario, only a portion of the energy required by the load is compensated, leading to an extension between recharges. For example, if the energy harvested compensates 50% of load’s energy, then the battery lifetime is effectively doubled.

Alternatively, if the harvester compensates 100% or more of the energy consumed by the load, then the application will be autonomous in energy. This is the plug-and-forget concept and is the main goal of implementing energy harvesting. As products that continuously operate requiring zero user-intervention during their entire life are more attractive than traditional battery-powered alternatives.

To achieve this, designers usually consider the worst-case scenario in consumption and in light. For example, we know that the prices displayed in an Electronic Shelf label are normally changed a few times a week. But for system dimensioning, this can be specified as multiple updates per day.

Designing differently

For many system engineers it means looking at how they can rethink their design to make the most of rechargeable batteries with indoor light energy harvesting using miniature solar cells. For example, optimizing the battery and solar cell choice is key to making systems energy autonomous using an energy harvesting power management IC (PMIC).

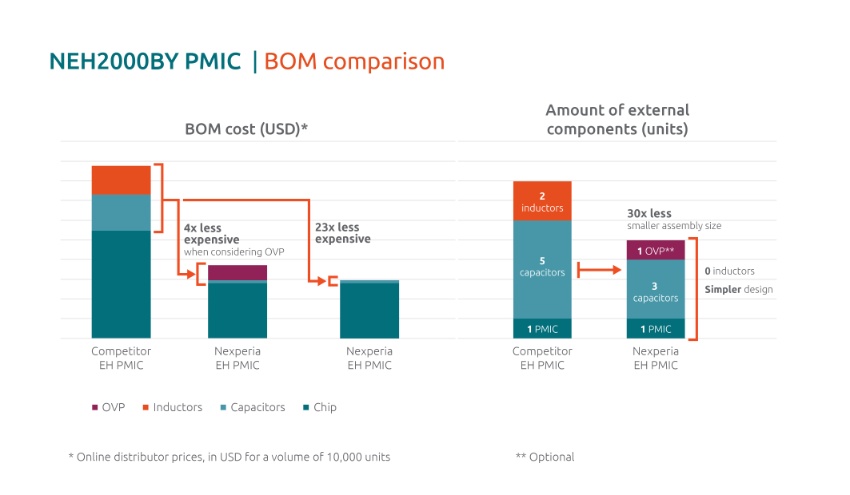

Nexperia’s energy harvesting PMICs are ultra-compact, high-performing chipsets featuring reduced BOM cost and ultra-fast Maximum Power Point Tracking (MPPT). They require no inductors and are remarkably simple to design in. This unique combination along with the ability to adapt to changes in the environment, is key to delivering a compelling alternative to traditional battery power. Reducing upfront costs and engineering time and thereby reducing the total resources spent on the product.

By continuously harvesting energy from the environment into consumer electronics and IoT devices with clean ambient energy, our energy harvesting PMICs remove the need for battery swaps, contributing to a more sustainable future for electronics.

For more information, check out our energy harvesting PMICs page.