We see a number of trends in today’s electronic systems such as the move to faster switching and higher voltages, in particular 48 V for automotive and industrial designs. That naturally draws the focus towards MOSFETs and wide bandgap FETs. However, there remains a significant need for more simplified switching even in 48 V EV systems. With latest addition to Nexperia’s Resistor Equipped Transistors (RETs) portfolio, designers have the option of using a high-performance Bipolar Junction Transistor with an integrated bias resistor often known as a digital transistor.

Fast, high-power switching plays a key role in many of today’s automotive and industrial applications as we push performance ever higher. But it is not the complete story. Every system or sub-system has a range of switching requirements. And for low frequency medium voltage switching, RETs or digital transistors are commonplace. Often used to provide a simple way to switch and drive loads directly from logic devices they offer benefits including space savings, reduced manufacturing costs and increased reliability and robustness.

How does a RET or digital transistor work?

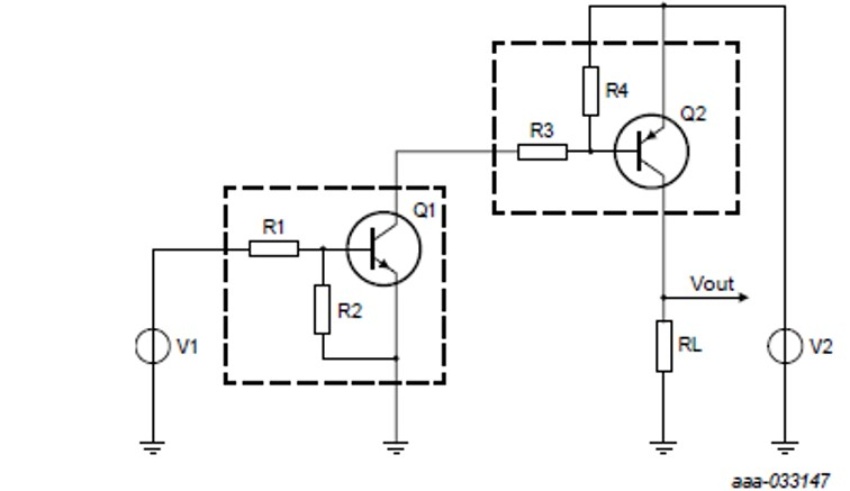

Bipolar transistors are controlled using the base current. But because the voltage drop across the base-emitter path is highly temperature-dependent, in most applications a series resistor is required to keep the base current at the desired level. This ensures stable and safe operation of the transistor.

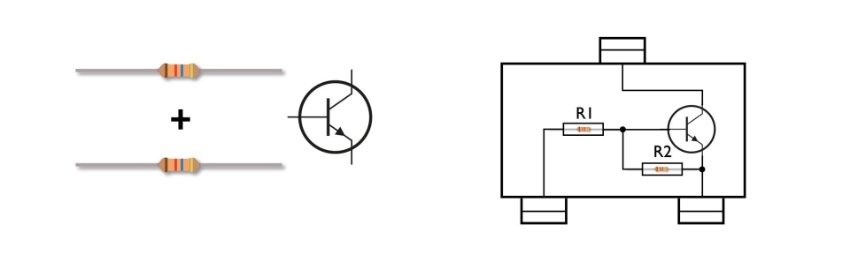

To reduce component counts and simplify board designs, RETs combine single or dual bipolar transistors with the bias resistors integrated on the same die. An alternative option is to include a second integrated in parallel to the base-emitter path as a base divider, which provides fine tuning and better turn-off characteristic behaviour. Because these internal resistors have higher tolerances than commonly used external resistors, RETs are suitable for switching applications where the transistor operates in either on- or off-state.

A proven portfolio

Nexperia’s RET portfolio has been supporting this often-overlooked role for many years. Providing a broad selection covering numerous voltage and current ratings, both NPN and PNP configurations, and in a variety of packages including SOT23 variants. Dual versions with two transistors and four resistors are also available.

For the integrated resistors, Nexperia offers R1 values from 2.2 kΩ to 47 kΩ and R2 values from 10 kΩ to 47 kΩ. The ratio of the resistors R2/R1 can be 1, 2.13, 4.55, 10 and 21. A benefit of Nexperia’s technology is the relative tight tolerance of the integrated resistors with current values above 100 mA. At +/-10% these are three times more accurate than other products, enabling the input voltage safety margin to be reduced.

80 V automotive RETs

BJTs are preferred in many automotive applications due to their robustness, and Nexperia’s standard 50 V RETs can be found in many 12 V automotive applications. However, the growth in electric vehicles with a 48 V board net means more headroom has become necessary. Nexperia’s 80 V RETs provide the safe operating margin required.

There is another driver. Automotive customers now require devices that meet pulse tests in accordance with ISO 7637-2:2011 – the standard defining robustness against transients along the power supply bus. Nexperia’s 80 V RETs have been tested and withstand the required 20 V across base-emitter junction. This is vital for 24 V systems in trucks and lorries, and 48V automotive systems.

For more details on how Nexperia’s RETs perform, check out or download the application note.