When compared to their integrated circuit counterparts, who are spoiled by the most comprehensive simulation models, board level designers working with discrete power MOSFETs must feel terribly cheated. Many of the models for these devices are patchy at best, providing limited insight into how they will perform across temperature and voltage, and some completely fail to capture important device behaviour. It is not uncommon for designers to be only able to simulate at a nominal temperature (e.g., 25 °C) and then use a mixture of experience and educated guesswork so that their designs have enough margin to cope with the expected worse-case scenarios. For some performance characteristics, like electromagnetic compatibility (EMC), they cannot get any insight into how their circuits will perform until a board is built and testing is performed. If this then becomes an issue, a costly and time-consuming debug and redesign to fix the problem may even be necessary. Therefore, board designers will be delighted to know that things are about to improve, in the guise of a new set of advanced electrothermal models which Nexperia have developed for their discrete MOSFETs. Let’s delve deeper to find out why.

Standard Model Shortcomings

To correctly predict the switching and EMC behaviour of a MOSFET, it is important to have an exact model of its static and dynamic characteristics across the full operating temperature range. This information allows designers to perform accurate circuit simulations using a SPICE software package. Standard models from many manufacturers do not provide all this information, meaning discrete designers sometimes must err on the side of caution by assuming worst case scenarios will occur. This often leads to designs which are over-specified for an application, potentially making them bigger and more expensive than necessary.

Reverse recovery diode behavior

During double-pulse testing, the reverse recovery charge (Qrr) of the upper device in a half-bridge creates a short-duration, high-frequency transient signal (referred to as reverse recovery current) which interacts with the parasitics on the PCB and in the MOSFET itself. This affects the EMC performance of the circuit because of the voltage and current overshoots which result. This behavior is not normally captured in the simulation models provided by many manufacturers and as a result, the magnitude of the ringing caused at second switch-on can appear to be quite large. For example, Figure 1 shows the results of a double-pulse simulation using a set of standard MOSFET models which shows a 75% voltage overshoot lasting for almost 0.5 microseconds. When real devices are subsequently evaluated in the lab, this amount of ringing does not typically occur in practice.

.png)

Nexperia’s Advanced Electrothermal Models

Nexperia have developed a new set of advanced electrothermal models for use with SPICE and VHDL-AMS that more accurately capture the behavior of their power MOSFET devices, including the reverse recovery of the body diode. For example, Figure 2 shows the results of the same device simulation (a BUK7S1R0-40H N-channel 40 V,1mΩ MOSFET in LFPAK88) performed previously, but which uses these advanced models. Much less ringing is evident, and oscillations settle out in a much shorter time interval (less than 0.2 microseconds) than was the case using standard models.

.png)

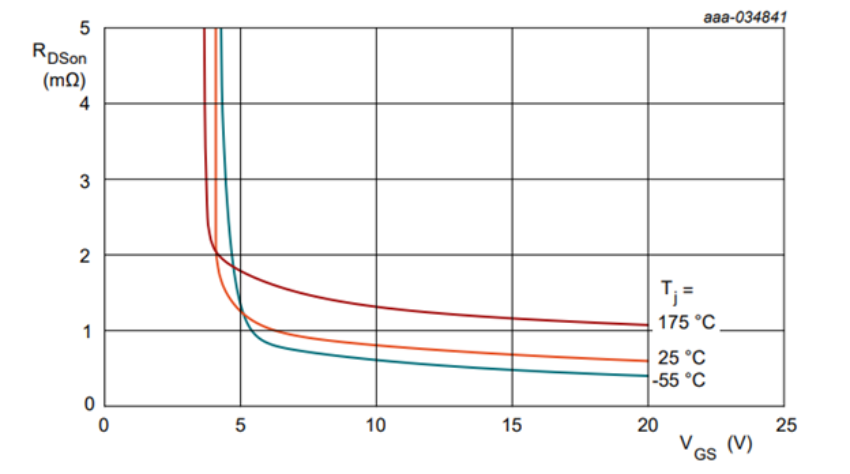

These models can also be used to investigate device performance across their full operating temperature range. Figure 3 shows the simulated on-resistance (RDS-ON) for the same MOSFETs at temperatures ranging from -55°C and 175°C.

A Brighter Future for Board Designers

The limitations of standard power MOSFET simulation models have often resulted in designs being unnecessarily over-specified or problems going undetected until late in the product development process, when they become difficult and expensive to address. Nexperia’s advanced electrothermal models more accurately reflect device behavior across the full operating temperature range. This is a major advance on standard models because it allows designers to be more confident in the results of their SPICE simulations and to understand the EMC performance of their circuit at a much earlier stage in the development process.